Highly efficient phosphor-glass composites by pressureless sintering

- Select a language for the TTS:

- UK English Female

- UK English Male

- US English Female

- US English Male

- Australian Female

- Australian Male

- Language selected: (auto detect) - EN

Play all audios:

ABSTRACT The development of high-power white light-emitting diodes demands highly efficient and stable all-inorganic color converters. In this respect, phosphor-glass/ceramic composites show

great promise as they could combine the merits of high quantum efficiency of phosphors and high chemical and thermal stabilities of glass/ceramic matrices. However, strong interfacial

reaction between phosphors and matrices at high temperature results in quantum efficiency loss of the embedded phosphors, and traditional solutions rely on high-pressure consolidation

techniques. Here we report the intrinsic inhibition of interfacial reaction by using silica glass rather than multicomponent glasses as the matrix. The embedment of phosphors is achieved via

a pressureless sintering method, rendering these color-tunable phosphor-glass composites not only accessible to three-dimensional printing technique, but also highly efficient (internal

quantum efficiency >90.0%), thermally stable at 1200 °C and hydrothermally stable at 200 °C. Our results provide a facile and general strategy for developing all-inorganic functional

composites. SIMILAR CONTENT BEING VIEWED BY OTHERS RAPID SINTERING OF HIGH-EFFICIENCY PHOSPHOR-IN-GLASS FILMS FOR LASER-DRIVEN LIGHT SOURCE Article Open access 21 March 2025 RAPID SYNTHESIS

OF PHOSPHOR-GLASS COMPOSITES IN SECONDS BASED ON PARTICLE SELF-STABILIZATION Article Open access 03 February 2024 DESIGN OF MECHANICAL-ROBUST PHOSPHORESCENCE MATERIALS THROUGH COVALENT CLICK

REACTION Article Open access 05 August 2023 INTRODUCTION Color converters that can emit light of desired wavelengths after absorbing incident light play a key role in light-emitting1,2,3

and -detecting4 devices as well as photovoltaics5,6. However, conventional color converters with luminescent particles embedded in transparent organic polymers are notoriously easy to

degrade during exposure to heat, moisture and short-wavelength radiation, leading to much shorter lifetime of the devices than expected7,8. Recently, the so-called phosphor-converted white

light-emitting diodes (pc-WLEDs) have been widely used in general lighting and display backlighting, but their extension to high-power and high-brightness lighting fields such as street

lighting, automotive headlamp and large-size display, is extremely sluggish1,2,3,9,10. Besides thermal quenching of phosphors1,3,9,11, unacceptable degradation of organic resins under

intense blue/near-UV radiation and high temperature (>150 °C) becomes a major obstacle7,8,9,10. Traditional doped single-phase (or eutectic) transparent ceramics12,13 and bulk crystals14

are efficient all-inorganic color converters whereby organic encapsulation could be circumvented, but the costly preparation and the very limited variety exclude them from mass production

and general application9. In contrast, directly consolidating the mixtures of commercial phosphors and glass/ceramic powders into bulk composites is believed to be a much more feasible and

economical strategy10,15,16,17,18,19, partly because of the diverse selection of phosphors and matrix compositions. Generally, more thermally stable matrix requires higher sintering

temperature for full densification, whereas strong interfacial reaction with matrix at high temperature (>800 °C) will corrode the phosphor particles. As in other composite

materials20,21,22, the most fundamental issue here is how to preserve the intactness of the embedded phosphors so that the composites could retain the luminescence properties of the raw

phosphors. Many researchers have sought to inhibit the interfacial reaction by adopting low-melting glasses (such as low-silica16,19,23, tellurite17,18 and phosphate24,25 glasses) and

ceramics (CaF226 and hydroxyapatite27) as the matrix, and/or resorting to high-pressure and high-vacuum techniques like hot isostatic pressing25, spark plasma sintering (SPS)27,28 and gas

pressure sintering29. However, high quantum efficiency (QE) of phosphors is seldom retained by these strategies even though they have sacrificed the high chemical and thermal stabilities and

the facile synthesis10. Moreover, those reported matrices suffer from certain disadvantages including low visible transparency17,24,25,26,27, high price17,18 and heavy metal (for example,

Pb and Sb) containment30,31. On the other hand, high-pressure consolidation techniques not only require sophisticated equipment, but also are limited to manufacturing plate-like objects, so

that three-dimensional (3D) structure, for example the preferred hemispherical dome32,33,34, is hardly realized for all-inorganic color converters. Hence, the development of color converters

that are highly efficient, chemically and thermally stable, cost-effective, and easy to shape remains an important but challenging task. Silicon (Si) is the second most abundant element in

the earth’s crust, and is nontoxic. Fused silica (SiO2) glass, known for optical fibers, possesses outstanding chemical and thermal stabilities as well as high visible transparency, possibly

being an excellent matrix for phosphors. Nevertheless, the ultra-high melting temperature (>1700 °C) makes efficient phosphors in silica glass (PiSG) composites only accessible to

expensive SPS systems by far28. Here we report the facile synthesis of PiSG by a reduction sintering method, where amorphous silica nanoparticles are utilized to facilitate the densification

process and develop photocurable composite slurries. Through exploiting the temperature- and composition-dependent solid solubility of Si4+ in phosphors, we find that interfacial reaction

between phosphors and silica glass could be well suppressed even at the temperature of 1250 °C. We further demonstrate that the perfect combination of phosphors and silica glass with

negligible interfacial reaction produces a series of highly efficient (for Y3Al5O12:Ce (YAG:Ce) in silica glass, internal QE (IQE) = 95.0%), chemically and thermally stable phosphor-glass

composites. By virtue of pressureless sintering, we also realize the freeform fabrication of all-inorganic color converters for the first time by combining with modern 3D printing

technology. RESULTS DESIGN AND SYNTHESIS OF YAG:CE-PISG Despite extensive research in developing new phosphors for pc-WLEDs1,2,3,11, the yellow phosphor YAG:Ce is still the dominant one

owing to its suitable excitation and emission spectra, high IQE, and superior chemical and thermal stabilities35. Therefore, as a demonstration, we first designed and synthesized

YAG:Ce-PiSG. The crystal structure of YAG:Ce is thermally stable up to 1700 °C36, and its IQE can be well maintained after heat treatment for 3 h at 800 °C in air (Supplementary Fig. 1), but

YAG:Ce-glass/ceramic composites sintered at 700 °C for less than 30 min show obvious IQE loss19,26,27, suggesting that using low-melting materials is not an effective way to inhibit

interfacial reaction. Among various glass systems, silicate glasses with high silica content are the optimal matrix materials for their high chemical and thermal stabilities. Large amounts

of glass modifiers like Na+, Zn2+ and Ca2+ are usually added to reduce the melting point19,23,30, which, in turn, will cause intrinsically more severe corrosive reaction of glass matrix with

phosphor owing to the high reactivity and diffusivity of those low-valence ions10,37 and the presence of non-bridging oxygen atoms18. Particularly, while the flexibility in composition of

garnet structure allows high co-solubility of low-valence ions and Si4+ in YAG34, the solubility of Si4+ in YAG is very low (<0.1%) due to the size and charge mismatches between Si4+ and

Al3+/Y3+38. Hence, we reasoned that interfacial reaction could be essentially inhibited by embedding YAG:Ce into pure silica glass instead of multicomponent glasses. Previous investigation

on YAG transparent ceramics has shown that the sintering aid SiO2 starts to react with YAG in the vicinity of 1400 °C39. To lower the densifying temperature away from 1400 °C and

simultaneously avoid the use of high pressure and high vacuum, we chose amorphous silica nanoparticles with high sintering activity as the precursor to facilitate the densification process.

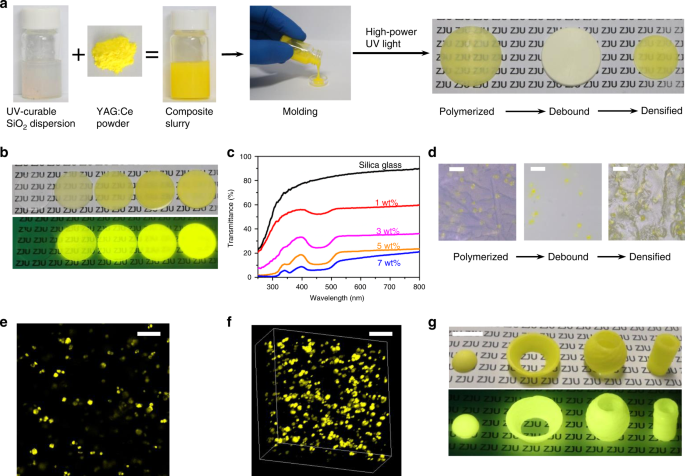

A large quantity of amorphous silica nanoparticles (53.7 wt%) are fully dispersed into a UV curable monomer mixture based on 2-Hydroxyethyl methacrylate (HEMA) to form a low-viscosity silica

dispersions40, and then YAG:Ce powders are added to obtain the final composite slurry where YAG:Ce particles can be well suspended (Fig. 1a). The slurry is then polymerized into transparent

flat-plate green bodies within 30 s under high-power UV light. Green bodies with complex 3D structure can be also rapidly produced from the developed photocurable slurry with

stereolithography (SLA) 3D printing (Supplementary Fig. 2), by which Kotz et al have recently fabricated various silica glass structure parts41,42. After two-step heat treatment for

debinding and densifying (Methods), the green bodies become porous and then are fully densified into transparent pure silica glass or translucent yellow YAG:Ce-PiSG (Fig. 1a,b), where for

PiSG doped with 1 wt% YAG:Ce (1 wt% YAG:Ce-PiSG) the linear shrinkage is 4.7 and 27.9% after debound and densified, respectively. As shown in Fig. 1c, pure silica glass exhibits excellent

transparency with a total transmittance of 80.5% at the wavelength of 450 nm (86.2% at 600 nm), implying that full densification is achieved. With incorporating YAG:Ce into silica glass, the

as-synthesized samples become translucent, accompanied by intense yellow emission upon 450 nm excitation (Fig. 1b). Transparency reduction is mainly attributed to the enhanced light

scattering due to the different refractive indices of YAG:Ce (1.84) and silica glass (1.46); nevertheless, moderate light scattering is beneficial to the color uniformity and the light

extraction of high-power pc-WLED, especially when laser diodes (LDs) are used as the excitation source9. Fluorescence microscope images (Fig. 1d) indicate that the size of YAG:Ce particles

remains constant (10–20 μm) as YAG:Ce/silica composite is polymerized, debound and densified. A confocal laser scanning microscope (CLSM) with a 488 nm laser is employed to investigate the

distribution of YAG particles inside silica glass. It can be clearly seen from the surface and 3D reconstruction CLSM images (Fig. 1e,f) that bright yellow points are uniformly dispersed in

silica glass. The quick UV curing used here greatly alleviate the phosphor sedimentation, an intractable problem existing in the heat-curing process of the sol-gel method (>12 h)43 as

well as conventional organic encapsulation (1.5 h)44. To accomplish rapid manufacturing of YAG:Ce-PiSG with complex shapes and inspired by the sintering of transparent ceramics in pure

hydrogen atmosphere45, we adopted a reduction (5%H2 + 95%N2) sintering method that are usually used for preparing phosphor powders, to quicken the densifying process and protect Ce3+ of

YAG:Ce-silica composite from oxidation at high temperature. In addition to its convenience and cost-effectiveness, another significant advantage of this strategy over those pressure-assisted

methods is maintaining the original shapes of green bodies after densification. Accordingly, by combining with the SLA 3D printing technique41, we realized the 3D construction of

YAG:Ce-PiSG (see Fig. 1g), which is extremely difficult for traditional tableting-sintering and melting-quenching methods10. It takes only 74 min for our desktop 3D printer to print one

batch (18 pieces) of dome-type parts (Supplementary Fig. 2) and the printing time could be further reduced via optimizing the printing conditions. With the development of 3D printing

techniques, rapid manufacturing of color converters with complex shapes will trigger off the modular assembly and mass customization of WLED lamps; for example, size-compatible dome-types

YAG:Ce-PiSG can directly replace the polycarbonate lens of blue LED chip (1 W) to form a WLED device (Supplementary Fig. 3). PERFORMANCE CHARACTERIZATIONS OF YAG:CE-PISG As shown in Fig. 2a,

the excitation and emission spectra of YAG:Ce-PiSG are the same with the corresponding YAG:Ce powder. Notably, benefiting from the high transparency of silica glass in the UV range, the

excitation band around 341 nm of YAG:Ce-PiSG is as high as that of YAG:Ce powder, which is absent or largely suppressed in those based on low-melting glasses/ceramics17,24,25,26,27. Under

450 nm excitation, the IQE of 5 wt% YAG:Ce-PiSG is determined to be as high as 95.0% (for YAG:Ce powder, IQE = 97.6%, Supplementary Table 3), meaning that nearly no IQE loss occurs when

YAG:Ce is embedded into silica glass. To the best of our knowledge, the as-synthesized YAG:Ce-PiSG is one of the most efficient all-inorganic color converters including transparent ceramics

and single crystals. As with YAG:Ce powder, YAG:Ce-PiSG shows fluorescence thermal quenching (Fig. 2b) at elevated temperature, and the decline of the integrated emission intensity of

YAG:Ce-PiSG is consistent with that of YAG:Ce powders, retaining higher than 80% of the initial value at 150 °C (Fig. 2c). The unimpaired luminescence properties of YAG:Ce-PiSG imply that

the intactness of YAG:Ce is well preserved when YAG:Ce-silica composite are consolidated into bulk materials at high temperature (1250 °C). High-temperature sintering naturally grants

YAG:Ce-PiSG a superior thermal stability. To confirm this unique feature, we baked YAG:Ce-PiSG at the temperature of 1200 °C in air for 10 h. The IQE and the appearance of YAG:Ce-PiSG are

both unchanged, while those low-melting inorganic materials phosphors not only suffer from obvious IQE loss but also soften or even melt at much lower temperature (Supplementary Fig. 4). For

fully estimating the moisture resistance at elevated temperature, a highly accelerated temperature and humidity test is necessary. Here we adopted a modified immersion test for YAG:Ce-PiSG

where the sample was immersed in distilled water and then hydrothermally treated for 10 h, which is much harsher than that for traditional optical glasses46. Although those low-melting

inorganic materials (except phosphate glasses) are thermally stable at <300 °C, all of them are moisture sensitive, especially when the temperature is higher than 100 °C (Supplementary

Fig. 4), which is insufficient to achieve ultra-long lifetime (ideally, 100,000 h) of pc-WLED devices. In comparison, YAG:Ce-PiSG is hydrothermally stable at 200 °C, manifesting its

satisfactory chemical and thermal stabilities for high-power LED applications. Another essential parameter of matrix materials for color conveters is the thermal conductivity because if the

huge amount of generated heat during LED operation cannot be dissipated quickly, it will give rise to strong thermal quenching of phosphors. YAG:Ce-PiSG has the thermal conductivity of 1.44

and 1.93 W m−1 K−1 at room temperature and 250 °C, respectively, which is eight times that of organic resins (∼0.2 W m−1 K−1) and also higher than that of those multicomponent glasses (for

example, 0.71 W m−1 K−1 for tellurite and phosphate glasses)17,24. These results indicate that YAG:Ce-PiSG combines the excellent luminescence properties of YAG:Ce with the outstanding

chemical and thermal properties of silica glass, without sacrificing the easiness of fabrication. To demonstrate the performance of YAG:Ce-PiSG in practical LED applications, we fabricated a

high-power (10 W) pc-WLED device (Fig. 2d), and the electroluminescent spectrum is shown in Fig. 2e. The luminous efficiency (LE) is as high as 119 lm W−1 at 50 mA, and the luminous flux

can reach 785 lm at 1000 mA with LE decreasing to 86 lm W−1 due to the so-called “efficiency droop” of the LED chip under high operating current (Fig. 2f)47. This performance can be further

improved by optimizing the scattering effect inside the PiSG composite and using blue LED chip with higher radiant efficiency. In order to evaluate the capability to withstand high-density

blue radiation, we focused a power-tunable 455 nm laser on the YAG:Ce-PiSG plate without any heat sink (Fig. 2g). The luminescence saturation for YAG:Ce-PiSG occurs at the optical power

density of 2.72 W (3.46 W mm−2) (Fig. 2h), which is six times higher than that (0.5 W mm−2) for those multicomponent silicate glass matrices9,19. In contrast to silicone and those

low-melting materials that cannot survive at higher than 1 W mm−219, owing to the high chemical and thermal stabilities, YAG:Ce-PiSG could serve as a good color converter for laser-driven

lighting if heat sink like sapphire plate9, is added. STRUCTURAL EVIDENCES FOR INHIBITED INTERFACIAL REACTION Although the incorporation of YAG:Ce induces the precipitation of silica glass

into cristobalite phase, multicomponent crystalline phase signifying the strong admixture of SiO2 with YAG:Ce cannot be detected by the powder X-ray diffraction (XRD) patterns (Supplementary

Fig. 5). We first used the scanning electron microscopy (SEM) coupled with energy-dispersive X-ray spectroscopy (EDS) to analyze the microstructrure of YAG:Ce-PiSG. As demonstrated by the

SEM images and EDS analysis (Fig. 3a and Supplementary Table 2), YAG:Ce-PiSG has a smooth surface with a very limited number of pores, and Y clusters with a diameter of 10–20 μm are

distributed in the Si matrix, confirming the successful preparation of YAG:Ce-PiSG. To study the interface reaction between YAG:Ce particles and glass matrix at nanometer scale, we conducted

transmission electron microscopy (TEM), selected area electron diffraction (SAED) analysis and TEM-EDS line scanning measurements for YAG:Ce-PiSG. The TEM image in Fig. 3b shows a clear

boundary representing the interface between YAG:Ce and glass matrix, which is evidenced by the concurrence of the diffraction spots belonging to amorphous SiO2 and YAG:Ce crystal in the SAED

pattern of the interface. In the TEM-EDS element spectra (Fig. 3c), the abrupt but opposite changes in the content of Y/Al and Si elements denote the interficial reaction zone, and the

thickness of the interface of YAG:Ce-PiSG is thus estimated to be about 150 nm. In comparison, this thickness is about 200 nm for YAG:Ce-PiG based on low-melting silicate glasses despite a

much shorter holding time (30 min)48,49. Solid-state nuclear magnetic resonance (NMR) spectroscopy is a powerful tool to provide atomic structural information in material science. Figure 3d

shows the 27Al magic angle spinning NMR (MAS-NMR) spectra of YAG:Ce powder and YAG:Ce-PiSG. The single-peak signal at 1.5 ppm and the well-defined quadrupolar peak at 71.3 ppm can be clearly

resolved, where the former represents six-coordinated Al (AlVI) and the latter four-coordinated Al (AlIV). The maximum peak positions, i.e. the average isotropic chemical shifts (δiso), as

well as the peak shapes of the two aluminum species show no difference in both spectra, indicating that the local environment of these polyhedrons remains nearly the same after YAG:Ce are

embedded into silica glass. The ratios of the integrated signal intensities of AlIV and AlVI species from YAG:Ce powder and YAG:Ce-PiSG are estimated to be 42.3:57.8 and 41.5:58.5,

respectively, both of which agree well with the expected 2:3 ratio for YAG crystal. In addition, the 29Si MAS-NMR spectra of pure silica glass and YAG-PiSG (Supplementary Fig. 6) are almost

identical, which is consistent with the results from 27Al MAS-NMR spectra. Moreover, the long-term (10 h) high-temperature stability of YAG:Ce-PiSG at 1200 °C also reflect the intrinsically

inhibited interfacial reaction between YAG:Ce and silica glass. Our results unambiguously confirm that interfacial reaction between YAG:Ce and silica glass matrix is very limited even at

1250 °C for 3 h. VERSATILE PHOSPHOR-SILICA GLASS COMPOSITES The extremely small diffusion rate of highly charged Si4+ and the absence of non-bridging oxygens18,28 largely improve the

activation energy (namely the required temperature) for the interfacial reaction of phosphor with silica glass, as compared with multicomponent glasses. Moreover, a reduction atmosphere is

employed not only to assist the densification process, but also to preserve Ce3+ and Eu2+, two most widely used activators in phosphors, which otherwise would be oxidized into luminescence

killers (Ce4+ and Eu3+) at high temperature. Using amorphous silica nanoparticles lower the required temperature to only 1250 °C, but, nevertheless, the structure of most phosphors including

oxides and oxynitrides are thermally stable at this temperature. Therefore, the proposed strategy can generally be applied to achieve color tunable emission in silica glass based

composites. As shown in Fig. 4, not only garnet-type phosphors including Lu3Al5O12:Ce (LuAG:Ce, blue-green), (Gd,Y)3Al5O12:Ce (GdAG:Ce, orange) as well as YAG:Ce (yellow), but other

well-known phosphors such as BaMgAl10O17:Eu (BAM:Eu, blue), β-SiAlON:Eu (β-Sialon:Eu, green) and Al2O3:Cr (far-red) were particularly incorporated into silica glass for exemplification (Fig.

4). As expected, all the as-synthesized phosphor-glass composites are highly efficient with limited IQE loss except the β-Sialon:Eu doped one (Supplementary Table 3). Unlike α-sialon,

β-sialon is structurally unstable at high temperature due to N2 evaporation43, resulting in large IQE loss. Using smaller amorphous silica nanoparticles (<15 nm) or tetramethoxysilane as

the precursor43,50 could reduce the required temperature to lower than 1100 °C. It is thus anticipated that more kinds of phosphors could be incorporated into silica glass without obvious

IQE loss. However, the densifying temperature of silica glasses is still too high for red nitride phosphors, and this limitation cannot be well circumvented until novel oxide or oxynitride

red phosphors with high thermal stability are developed. Finally, silica glass acts as an effective buffer for the embedded phosphors against oxidation at high temperature (Supplementary

Fig. 4), which will endow them with better performance as the thermographic phosphor for high-temperature (>1000 °C) thermometry36. DISCUSSION In summary, we have developed a reduction

sintering method for rapid producing highly efficient phosphor-silica glass composites. Such a pressureless consolidation technique is compatible with modern 3D printing technique, thus

enabling the 3D construction of all-inorganic color converters that are thermally stable up to 1200 °C. We confirmed that interfacial reaction between phosphors and silica glass is

intrinsically inhibited without adding any glass modifier cations, and the resultant composites possessing excellent luminescence properties, shows great potential for high-power and

high-brightness pc-WLEDs. Our work provides a facile and general synthetic strategy to color-tunable bulk composites based on silica glass for various light-emitting and light-detecting

applications, which also have strong implications for developing innovative glass based composite materials with high-temperature stability51. METHODS MATERIALS HEMA (99%), tetra(ethylene

glycol) diacrylate (TTGDA), Diethylene glycol dibenzoate (DEDB, 99.5%), 2,2-dimethoxy-2-phenylacetophenone (DMPA, 99%) and Sudan red G (95%) were purchased from Aladdin, China. Tinuvin 1130

(Basf, Germany). Amorphous silica nanoparticles (a mean diameter of 40 nm, Aerosil OX50) were purchased from Evonik, Germany. Except Al2O3:Cr3+ prepared by ourselves, all other phosphors are

commercially available from phosphor manufacturers (β-Sialon:Eu only from Mitsubishi Chemical, Japan). MOULDING AND 3D PRINTING OF GREEN BODIES Figure 1a shows the detailed manufacturing

process of YAG:Ce-PiSG. 28.1 wt% HEMA, 14.5 wt% DEDB and 3.7 wt% TTGDA were thoroughly mixed. Then, 53.7 wt% amorphous silica nanoparticles were added to the monomer mixture in 100 times and

stirred with an agitator (D500 DragonLab) after each addition to form the dispersion. Afterwards, 0.4 wt% DMPA was added into the dispersion (with respect to the amount of reactive

monomer). Note that for SLA 3D printing 0.02 wt% Sudan red G was added. Finally, YAG:Ce powder (1–7 wt% with respect to the amount of silica nanoparticles) was mixed into the dispersion,

which was defoamed using a vacuum ball mill for 1 h. After that, a homogeneous slurry containing silica nanoparticles and YAG:Ce powders was obtained. For disc-like plates of green bodies,

the photopolymerization was performed under a high-power UV lamp (365 nm, 1000 W, 273 mW cm−2) for 25 s. In the 3D printing process, a desktop LCD SLA 3D printer (L1121, isun3d, China) was

used. It has a 3.5-inch LCD screen with a resolution of 2560 × 1140 DPI and an array of 405 nm LEDs as the light source. 3D models for printing were designed using SolidWorks (Dassault

Systèmes, France) software and exported in the STL file format. The STL files were then imported into the 3D printing software (ChiTu Slicer, China) for slicing and printing. The printing

process is automatic and the printing time of one batch depends on the height of the designed parts and the scanning speed of UV light. Finally, the printed green bodies were immersed into

isopropyl alcohol for two minutes to remove the surface attachment. To demonstrate the modularization of pc-WLEDs, the size of the hemispherical dome of YAG:Ce-PiSG was designed according to

mid-power (1 W) 450 nm LED chip so that the polycarbonate lens can be directly replaced by the as-prepared YAG:Ce-PiSG and sealed with heat conducting silicone (Supplementary Figs. 2 and

3). SINTERING OF YAG:CE-PISG The green bodies were first heat-treated at 600 °C in air for 6 h with a heating rate of 1 °C min−1 using a box furnace (KSL-1100X, HF-Kejing, China). Then, they

were sintered at 1250 °C in reducing atmosphere (5%H2 + 95%N2) (0.1 L min−1) for 3 h with a heating rate of 3 °C min−1 in a high-temperature tube furnace (GSL-1400X, HF-Kejing, China).

Finally, the obtained YAG:Ce-PiSG was polished for measurements. Other phosphors embedded PiSGs were synthesized by the same procedures with YAG:Ce-PiSG. CHARACTERIZATION The transmittance

spectra were measured with a UV-vis-infrared spectrometer (U-4100, Hitachi, Japan). Fluorescence microscope image was recorded on the fluorescence microscope (BX53, Olympus, Japan) in the

bright-field mode. The distribution of phosphor particles within silica glass was analyzed by using a confocal laser scanning microscope (TCS SP5, Leica, Germany). The emission, excitation

and temperature-dependent emission spectra were measured on FLS920P spectrometer (Edinburgh Instruments, UK), where the temperature was controlled by a high-temperature fluorescence test

device (TAP-02, Orient KOJI). The IQE and Absorption were measured with a UV-NIR absolute photoluminescence quantum yield spectrometer (Quantaurus-QY Plus C13534-12, Hamamatsu Photonics,

Japan), where the error is within 1%. The thermal conductivity measurement was performed by a physical performance measurement system (PPMS, Quantum Design DynaCool-9). All the

high-temperature stability tests were conducted in air with a tube furnace. The chemical stability was characterized by a highly accelerated temperature and humidity stress test that the

samples are immersed in distilled water and hydrothermally treated at higher than 100 °C for 10 h using a stainless-steel reactor with a Teflon lining, which is much harsher than the

standard D85 test (85 °C and 85% relative humidity) as well as the normal hydrolytic resistance test for optical glass46. The XRD patterns were obtained on a powder XRD spectrometer (D/MAX

2550/PC, Rigaku, Japan). The SEM images were taken with a scanning electron microscope (Utral-55, Carl Zeiss, Germany), and a layer of gold was sputtered to the surface of the sample to

enhance the conductivity. The elementary composition (EDS and EDS mapping) was analyzed by an energy-dispersive spectrometer (INCA Energy Coater, Oxford Instruments) coupled to the SEM. TEM

image, SAED pattern and EDS line scanning were acquired on a JEM-2100 (JEOL, Japan) operating at 200 kV accelerating voltage. The sample was thinned using the TESCAN GAIA3 that integrates a

field emission SEM with a focused ion beam (FIB). Solid-state NMR spectra were obtained on a Bruker Avance III HD 500 M spectrometer (11.7 T). 27Al MAS-NMR spectra were recorded at a

resonance frequency of 130.3 MHz (27Al) using a 4 mm MAS-NMR probe at a spinning rate of 12 kHz. The pulse length was 0.56 μs (10°). The relaxation delay was 64 s for YAG:Ce-PiSG, and 40 s

for YAG:Ce powder. The chemical shifts of 27Al were referenced to an aqueous solution of 1 M Al(NO3)3. A resonance frequency of 99.3 MHz, a spinning rate of 8 kHz and a pulse length of 2 μs

(30°) were adopted to acquire the 29Si MAS NMR spectra. The relaxation delays of silica glass and YAG:Ce-PiSG were set as 350 s, and the chemical shifts were referenced to

tetrakis(trimethylsilyl)silane. LED/LD DEVICE FABRICATION AND MEASUREMENT High-power pc-WLED devices (Fig. 2d) were fabricated by combining 10 W 450 nm LED chips (Bridgelux, USA) with 5 wt%

YAG:Ce-PiSG (0.8 mm in thickness). A power adjustable 455 nm LD (LSR455CP-FC-12W, Lasever, China) was used as the excitation source to evaluate the capability of YAG:Ce-PiSG to withstand

high-density radiation. As shown in Fig. 2g, the laser was focused directly on 5 wt% YAG:Ce YAG:Ce-PiSG plate (1 cm in diameter, 0.6 mm in thickness) to form a prototype white LD device,

where the beam is nearly circular and the spot size was fixed at a diameter of 1.0 mm (0.785 mm2). The optical output powers of the blue LD under different input currents were measured with

a laser power meter (PM100D, Thorlabs). The optical properties of white LED/LD devices including the electroluminescence spectra, _R_a, CCT, and LE were measured by an integrated test system

(LHS-1000, EVERFINE) including photoelectric characteristic testing system, high accuracy array spectrophotometer (HAAS-2000), stabilized DC power supply, and an integrating sphere

(SPEKTRON R98, Φ 80 cm). DATA AVAILABILITY All the data supporting the findings in this study are available in the paper and Supplementary Information. Additional data related to this paper

are available from the corresponding authors upon request. REFERENCES * Kim, Y. H. et al. A zero-thermal-quenching phosphor. _Nat. Mater._ 16, 543–550 (2017). Article ADS CAS PubMed

Google Scholar * Luo, J. et al. Efficient and stable emission of warm-white light from lead-free halide double perovskites. _Nature_ 563, 541–545 (2018). Article ADS CAS PubMed Google

Scholar * Hoerder, G. J. et al. Sr[Li2Al2O2N2]:Eu2+-A high performance red phosphor to brighten the future. _Nat. Commun._ 10, 1824 (2019). Article ADS PubMed PubMed Central CAS Google

Scholar * Chen, Q. et al. All-inorganic perovskite nanocrystal scintillators. _Nature_ 561, 88–93 (2018). Article ADS CAS PubMed Google Scholar * Wu, K., Li, H. & Klimov, V. I.

Tandem luminescent solar concentrators based on engineered quantum dots. _Nat. Photon_ 12, 105–110 (2018). Article ADS CAS Google Scholar * Meinardi, F., Bruni, F. & Brovelli, S.

Luminescent solar concentrators for building-integrated photovoltaics. _Nat. Rev. Mater._ 2, 1–9 (2017). Article CAS Google Scholar * Chang, M. H., Das, D., Varde, P. V. & Pecht, M.

Light emitting diodes reliability review. _Microelectron. Reliab._ 52, 762–782 (2012). Article Google Scholar * Huang, J. et al. Rapid degradation of mid-power white-light LEDs in

saturated moisture conditions. _IEEE Trans. Dev. Mater. Rel_ 15, 478–485 (2015). Article CAS Google Scholar * Li, S., Wang, L., Hirosaki, N. & Xie, R. J. Color conversion materials

for high-brightness laser-driven solid-state lighting. _Laser Photon. Rev._ 12, 1800173 (2018). Article ADS CAS Google Scholar * Lin, H., Hu, Tao, Cheng, Y., Chen, M. & Wang, Y.

Glass ceramic phosphors: towards long-lifetime high-power white light-emitting-diode applications. _Laser Photon. Rev._ 12, 1700344 (2018). Article ADS CAS Google Scholar * Xia, Z. et

al. Li substituent tuning of LED phosphors with enhanced efficiency, tunable photoluminescence, and improved thermal stability. _Sci. Adv._ 5, eaav0363 (2019). Article ADS PubMed PubMed

Central CAS Google Scholar * Nishiura, S., Tanabe, S. & Fujimoto, Y. Properties of transparent Ce:YAG ceramic phosphors for white LED. _Opt. Mater._ 33, 688–691 (2011). Article ADS

CAS Google Scholar * Ma, X. et al. Pressureless glass crystallization of transparent yttrium aluminum garnet-based nanoceramics. _Nat. Commun._ 9, 1175 (2018). Article ADS PubMed PubMed

Central CAS Google Scholar * Latynina, A. et al. Properties of Czochralski grown Ce,Gd:Y3Al5O12 single crystal for white light-emitting diode. _J. Alloy. Compd._ 553, 89–92 (2013).

Article CAS Google Scholar * Fujita, S. & Tanabe, S. Glass-ceramics and solid-state lighting. _Int. J. Appl. Glass Sci._ 6, 356–363 (2015). Article CAS Google Scholar * Lee, Y. K.,

Lee, J. S., Heo, J., Im, W. B. & Chung, W. J. Phosphor in glasses with Pb-free silicate glass powders as robust color-converting materials for white LED applications. _Opt. Lett._ 37,

3276–3278 (2012). Article ADS CAS PubMed Google Scholar * Zhang, R. et al. A new-generation color converter for high-power white LED: transparent Ce3+:YAG phosphor-in-glass. _Laser

Photon. Rev._ 8, 158–164 (2014). Article ADS CAS Google Scholar * Segawa, H. et al. Fabrication of glasses of dispersed yellow oxynitride phosphor for white light-emitting diodes. _Opt.

Mater._ 33, 170–175 (2010). Article ADS CAS Google Scholar * Zhang, X. et al. Improving the luminous efficacy and resistance to blue laser irradiation of phosphor-in-glass based solid

state laser lighting through employing dual-functional sapphire plate. _J. Mater. Chem. C_ 7, 354–361 (2019). Article Google Scholar * Yao, Y. et al. High temperature shockwave stabilized

single atoms. _Nat. Nanotechnol._ 14, 851–857 (2019). Article ADS CAS PubMed Google Scholar * Wang, X., Padture, N. P. & Tanaka, H. Contact-damage-resistant ceramic/single-wall

carbon nanotubes and ceramic/graphite composites. _Nat. Mater._ 3, 539–544 (2004). Article ADS CAS PubMed Google Scholar * Rodenas, T. et al. Metal-organic framework nanosheets in

polymer composite materials for gas separation. _Nat. Mater._ 14, 48–55 (2015). Article ADS CAS PubMed Google Scholar * Chang, Y. P. et al. An advanced laser headlight module employing

highly reliable glass phosphor. _Opt. Express_ 27, 1808–1815 (2019). Article ADS CAS PubMed Google Scholar * Xiang, X. et al. Towards long-lifetime high-performance warm w-LEDs:

Fabricating chromaticity-tunable glass ceramic using an ultra-low melting Sn-P-F-O glass. _J. Eur. Ceram. Soc._ 38, 1990–1997 (2018). Article CAS Google Scholar * Kudo, S. et al.

Encapsulation of nitride phosphors into sintered phosphate glass by pressureless firing and hot isostatic pressing. _J. Eur. Ceram. Soc._ 102, 1259–1268 (2019). Article CAS Google Scholar

* Gu, C. et al. A new CaF2-YAG:Ce composite phosphor ceramic for high-power and high-color-rendering WLEDs. _J. Mater. Chem. C._ 7, 8569–8574 (2019). Article CAS Google Scholar * Huang,

P. et al. Nano wave plates structuring and index matching in transparent hydroxyapatite-YAG:Ce composite ceramics for high luminous efficiency white light-emitting diodes. _Adv. Mater._ 32,

1905951 (2020). Article CAS Google Scholar * Zhou, B. et al. Enhancing the performance of Ce:YAG phosphor-in-silica-glass by controlling interface reaction. _Acta Mater._ 130, 289–296

(2017). Article CAS Google Scholar * Yoon, C. B. et al. Highly improved reliability of amber light emitting diode with Ca–α–SiAlON phosphor in glass formed by gas pressure sintering for

automotive applications. _Opt. Lett._ 41, 1590–1593 (2016). Article ADS CAS PubMed Google Scholar * Gong, M. et al. Novel synthesis and optical characterization of phosphor-converted

WLED employing Ce:YAG-doped glass. _J. Alloy. Comp._ 664, 125–132 (2016). Article CAS Google Scholar * Lin, H. et al. Phosphor-in-glass for high-powered remote-type white AC-LED. _ACS

Appl. Mater. Interface_ 6, 21264–21269 (2014). Article ADS CAS Google Scholar * Narendran, N., Gu, Y., Freyssinier-Nova, J. P. & Zhu, Y. Extracting phosphor-scattered photons to

improve white LED efficiency. _P__Phys. Status Solidi A_ 202, R60–R62 (2005). Article ADS CAS Google Scholar * Allen, S. C. Steven & Steck, A. J. A nearly ideal phosphor-converted

white light-emitting diode. _Appl. Phys. Lett._ 92, 143309 (2008). Article ADS CAS Google Scholar * Liu, Z., Liu, S., Wang, K. & Luo, X. B. Optical analysis of color distribution in

white LEDs with various packaging methods. _IEEE Photonic Tech. Lett._ 20, 2027–2029 (2008). Article ADS Google Scholar * Xia, Z. & Meijerink, A. Ce3+-Doped garnet phosphors:

composition modification, luminescence properties and applications. _Chem. Soc. Rev._ 46, 275–299 (2017). Article CAS PubMed Google Scholar * Aldén, M., Omrane, A., Richter, M. &

Sarner, G. Thermographic phosphors for thermometry: a survey of combustion applications. _Prog. Energ. Combust. Sci._ 37, 422–461 (2011). Article CAS Google Scholar * Iqbal, F., Kim, S.,

Yie, H., Kim, Y. & Kim, H. Effect of alkali metal oxides on reliability and degradation of phosphor-in-glass encapsulants for white LEDs. _Ceram. Int._ 42, 10393–10398 (2016). Article

CAS Google Scholar * Zamir, S. Solubility limit of Si in YAG at 1700 °C in vacuum. _J. Eur. Ceram. Soc._ 37, 243–248 (2017). Article CAS Google Scholar * Stevenson, A. J. et al. Effect

of SiO2 on densification and microstructure development in Nd:YAG transparent ceramics. _J. Am. Ceram. Soc._ 94, 1380–1387 (2011). Article CAS Google Scholar * Wozniak, M., Graule, T., de

Hazan, Y., Kata, D. & Lis, J. Highly loaded UV curable nanosilica dispersions for rapid prototyping applications. _J. Eur. Ceram. Soc._ 29, 2259–2265 (2009). Article CAS Google

Scholar * Kotz, F. et al. Three-dimensional printing of transparent fused silica glass. _Nature_ 544, 337–339 (2017). Article ADS CAS PubMed Google Scholar * Kotz, F. et al.

Fabrication of arbitrary three-dimensional suspended hollow microstructures in transparent fused silica glass. _Nat. Commun._ 10, 1–7 (2019). Article ADS CAS Google Scholar * Yoshimura,

K. et al. Optical properties of green-emitting β-sialon:Eu phosphor-containing silica glasses and their deterioration mechanism. _Jpn. Appl. Phys._ 56, 060302 (2017). Article ADS Google

Scholar * Han, J. K. et al. Phosphor development and integration for near-UV LED solid state lighting. _ECS J. Solid State Sci._ 2, R3138–R3147 (2013). Article ADS CAS Google Scholar *

Zhang, J., An, L. Q., Liu, M., Shimai, S. & Wang, S. W. Sintering of Yb3+: Y2O3 transparent ceramics in hydrogen atmosphere. _J. Eur. Ceram. Soc._ 29, 305–309 (2009). Article CAS

Google Scholar * Bach, H. & Neuroth, N. _The Properties of Optical Glass_. (Springer-Verlag, New York, 1998). Book Google Scholar * Wasisto, H. S., Prades, J. D., Gulink, J. &

Waag, A. Beyond solid-state lighting: miniaturization, hybrid integration, and applications of GaN nano-and micro-LEDs. _Appl. Phys. Rev._ 6, 041315 (2019). Article CAS Google Scholar *

Chen, L. Y. et al. High-performance glass phosphor for white-light-emitting diodes via reduction of Si-Ce3+:YAG inter-diffusion. _Opt. Mater. Express_ 4, 1808–1815 (2014). Google Scholar *

Shyu, J. J. & Yang, C. W. Suppression of phosphor-glass reactions in YAG:Ce phosphor-embedded glasses. _J. Am. Ceram. Soc._ 100, 1460–1471 (2017). Article CAS Google Scholar * Ikeda,

H., Fujino, S. & Kajiwara, T. Preparation of SiO2-PVA nanocomposite and monolithic transparent silica glass by sintering. _J. Ceram. Soc. Jpn._ 119, 4 (2011). Article Google Scholar *

Davis, M. J. & Zanotto, E. D. Glass-ceramics and realization of the unobtainable: property combinations that push the envelope. _MRS Bull._ 42, 195–199 (2017). Article CAS Google

Scholar Download references ACKNOWLEDGEMENTS The authors thank Dr. Huajun Wu and Yongfu Liu for helping with the measurement of LED/LD devices, and Dr. Jiajia Zhou for helpful suggestion on

the manuscript. This work is financially supported by the National Key R&D Program of China (No. 2018YFB1107200), National Natural Science Foundation of China (Nos. 61775192, 51902286,

61905215 and 51772270), open funds of State Key Laboratory of Precision Spectroscopy (East China Normal University) and Wuhan Optoelectronic National Research Center (Huazhong University of

Science and Technology), and the Fundamental Research Funds for the Central Universities. AUTHOR INFORMATION Author notes * These authors contributed equally: Dao Zhang, Wenge Xiao, Chang

Liu. AUTHORS AND AFFILIATIONS * State Key Laboratory of Modern Optical Instrumentation, School of Optical Science and Engineering, Zhejiang University, Hangzhou, Zhejiang, 310027, China Dao

Zhang, Wenge Xiao, Beibei Xu & Jianrong Qiu * School of Materials Science and Engineering, Zhejiang University, Hangzhou, Zhejiang, 310027, China Chang Liu & Xiaofeng Liu * Key

Laboratory of Materials for High Power Laser, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai, 201800, China Jinjun Ren * CAS Center for Excellence in

Ultra-intense Laser Science, Shanghai Institute of Optics and Fine Mechanics, Chinese Academy of Sciences, Shanghai, 201800, China Jianrong Qiu Authors * Dao Zhang View author publications

You can also search for this author inPubMed Google Scholar * Wenge Xiao View author publications You can also search for this author inPubMed Google Scholar * Chang Liu View author

publications You can also search for this author inPubMed Google Scholar * Xiaofeng Liu View author publications You can also search for this author inPubMed Google Scholar * Jinjun Ren View

author publications You can also search for this author inPubMed Google Scholar * Beibei Xu View author publications You can also search for this author inPubMed Google Scholar * Jianrong

Qiu View author publications You can also search for this author inPubMed Google Scholar CONTRIBUTIONS W.X., C.L. and J.Q. conceived the idea and initiated the research. J.Q. supervised the

project. W.X. and J.Q. designed the experiments. D.Z., W.X. and C.L. performed the experiments and collected the data. W.X., D.Z., C.L., X.L. and B.X. analyzed the data and discussed the

results. J.R. conducted the solid-state NMR measurements and analyzed them. W.X., D.Z. and C.L. wrote the manuscript, and X.L., J.R., B.X. and J.Q. revised and commented on it. CORRESPONDING

AUTHORS Correspondence to Wenge Xiao or Jianrong Qiu. ETHICS DECLARATIONS COMPETING INTERESTS W.X., D.Z., C.L., J.Q. and X.L. are inventors on patent applications related to this work

(CN110128019A, CN110272208A and PCT/CN2019/122037). All other authors declare no competing interests. ADDITIONAL INFORMATION PEER REVIEW INFORMATION _Nature Communications_ thanks Mathieu

Allix and Woon Jin Chung for their contributions to the peer review of this work. Peer review reports are available. PUBLISHER’S NOTE Springer Nature remains neutral with regard to

jurisdictional claims in published maps and institutional affiliations. SUPPLEMENTARY INFORMATION SUPPLEMENTARY INFORMATION PEER REVIEW FILE RIGHTS AND PERMISSIONS OPEN ACCESS This article

is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give

appropriate credit to the original author(s) and the source, provide a link to the Creative Commons license, and indicate if changes were made. The images or other third party material in

this article are included in the article’s Creative Commons license, unless indicated otherwise in a credit line to the material. If material is not included in the article’s Creative

Commons license and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a

copy of this license, visit http://creativecommons.org/licenses/by/4.0/. Reprints and permissions ABOUT THIS ARTICLE CITE THIS ARTICLE Zhang, D., Xiao, W., Liu, C. _et al._ Highly efficient

phosphor-glass composites by pressureless sintering. _Nat Commun_ 11, 2805 (2020). https://doi.org/10.1038/s41467-020-16649-z Download citation * Received: 10 February 2020 * Accepted: 15

May 2020 * Published: 04 June 2020 * DOI: https://doi.org/10.1038/s41467-020-16649-z SHARE THIS ARTICLE Anyone you share the following link with will be able to read this content: Get

shareable link Sorry, a shareable link is not currently available for this article. Copy to clipboard Provided by the Springer Nature SharedIt content-sharing initiative